- LCD panel stripping solution regeneration cycle sy

- Waste mineral oil regeneration system program

- Coal-to-oil fee-based wax refining system solution

- Fish oil ethyl ester refining system program

- High-purity vitamin E refining system solution

- Biodiesel preparation system

- Plant extraction low temperature concentration sys

- Harmless treatment of toxic and refractory organic

- Polymer polymer removal monomer system

- Thermal product purification and purification syst

- Laboratory standard system set

- 0826-2232142

- No. 59, Hong Endong Road, Jingkai District, Mianyang City, Sichuan Province

- scjyhg@163.com

- Product Description

- Product Image

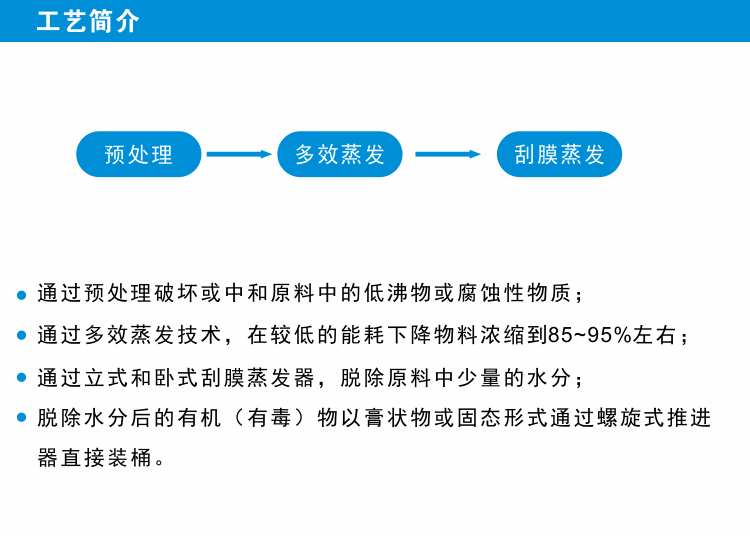

In industrial production, organic matter contained in printing and dyeing, tannery wastewater, etc. is difficult to biodegrade; through pretreatment to destroy or neutralize low-boiling or corrosive substances in raw materials, and then through multi-effect evaporation technology, lower energy consumption The material is concentrated to about 85~95%, and then a small amount of water is removed from the raw material through the vertical and horizontal wiped film evaporators; the organic (toxic) after removing the water is propelled in a spiral or solid form by spiral propulsion. Load the bucket directly. Our company provides customers with mature solutions for harmless treatment of toxic and difficult-to-degrade organic wastewater.